Roy SGS ceramic grain advantage

Low grinding power, low risky of burn

Low grinding power, low risky of burn

Grain self-sharpening feature can low down grinding power.

Giving longer wheel life

Giving longer wheel life

Due to the lower risky of burn, wheel grade and structure could be adjusted accordingly to reduce wheel dressing frequency, result in longer wheel life.

Increase wheel grinding efficiency

Increase wheel grinding efficiency

Due to the self-sharpening feature, there is the space to increase grinding infeed, travel speed etc parameters.

Roy TGA ceramic grain advantage:

Highly open structure

Highly open structure

The elongated structure creates by long grains lean on each other. Wheel natural packing density is very low.

High infeed

High infeed

The elongated structure creates an aggressive surface and an open structur with high permeability. Benifit to coolant works and worpieces chip move out.

Good wheel retention

Good wheel retention

Wheel bond is stronger for rod-shape grain than particle-shape grain, hence wheel retention is much better. Especially good for application request high retention. Like gear grinding, large bear race grinding, creep feed etc

Case Studies:

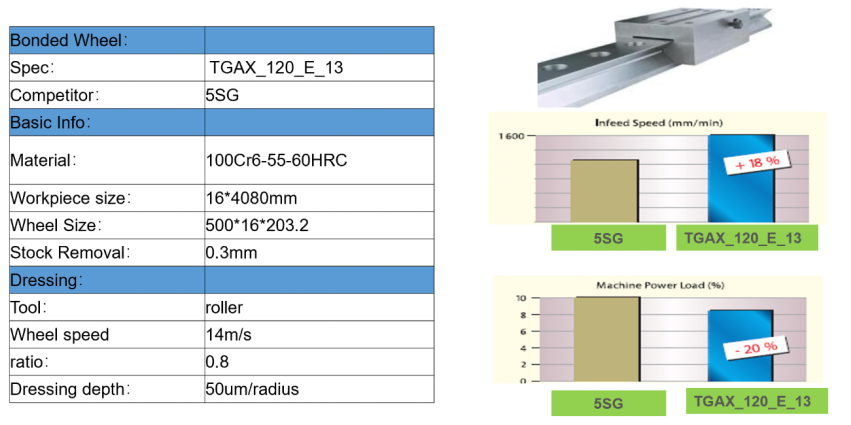

Case Study A:

Bonded ceramic grain wheel. (Internal grinding) – by Roy SGS (ceramic grain with particle-shape)

The grinding theory is different between conventional grain and ceramic grain. For conventional grain, the grain is broken at micro-meter size to have the edges for grinding. But for ceramic grain, it’s broken at nano-meter size.

Roy SGS grain crystalline is even smaller than 1st generation ceramic grain, which is well applied for grinding alloy, hard Cr-steel used in aerospace, auto etc. Wheel manufacture usually have this grain blended with conventional grain to low down the wheel cost.

Case Study B:

Bonded ceramic grain wheel. (Linear motion guide rail) – by Roy TGA (ceramic grain with rod-shape)

Roy TGA grain is a long rod-shape grain, is applied for high efficiency grinding

Roy TGA grain length / dia ration could be: 4:1 to 8:1. the longer the grain, the more open of the structure, more benefit for coolant working. Especially the length/dia = 8:1 grain, is the first shaped abrasive that holds an open structure without pore inducer. The wheel homogeneity, open, self-sharpening are all at the perfect situation.

The particular applications are: large bearing race grinding, aerospace, linear motion guide grinding, gear grinding including form gear, bevel gear and large modules worm gear grinding.

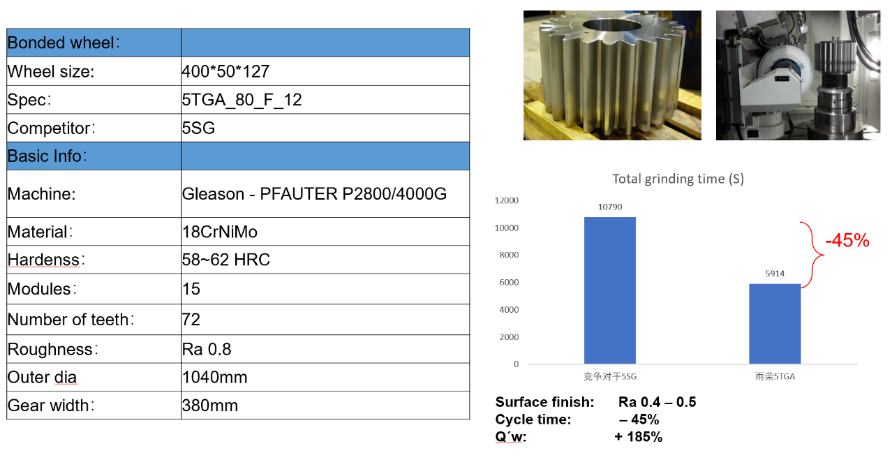

Case Study C:

Bonded ceramic grain wheel. (Form Gear Grinding) – by Roy TGA (ceramic grain with rod-shape)

Roy TGA grain is a long rod-shape grain, is applied for high efficiency grinding.

Roy TGA grain length / dia ration could be: 4:1 to 8:1. the longer the grain, the more open of the structure, more benefit for coolant working. Especially the length/dia = 8:1 grain, is the first shaped abrasive that holds an open structure without pore inducer. The wheel homogeneity, open, self-sharpening are all at the perfect situation.

The particular applications are: large bearing race grinding, aerospace, linear motion guide grinding, gear grinding including form gear, bevel gear and large modules worm gear grinding.

Download:

![]() Roy Product Case Study For BA Vitrified Wheel.pdf

Roy Product Case Study For BA Vitrified Wheel.pdf

-

Previous:Micro powder / Blasting Mar…

-

Next:Resin bonded wheel

Chinese

Chinese English

English