Ceramic Alumina Abrasive Inspection Method

For most grinding tooling manufacturers, they only have the capability to test common abrasive grains character such as appearance, particle distribution, loss pack density. For the key factor that affect grinding performance do not have capability to test. Here we introduce some easy method that can check the key characteristics.

Below is some good and bad case study:

Ceramic Alumina Abrasive Application Introduction

As the nano level fracture mechanism, ceramic alumina abrasive has advantage in application for better efficiency and longer wheel life. Usually they are mixed with fused alumina to achieve better grinding performance.

Common fused alumina and Ceramic alumina grains show different fracture mode when grinding. Mix of both can have better performance and wide application scope.

Ceramic alumina abrasives are mainly used for below applications:

Also ceramic alumina abrasives could be used for a number of other grinding applications. The manufacturer need consider the difference of each kind of ceramic alumina abrasives to balance the toughness and sharpness. And specialized bonding system is much needed for ceramic alumina abrasive tool manufacturing.

Technical Development Trend for Ceramic Alumina Abrasives

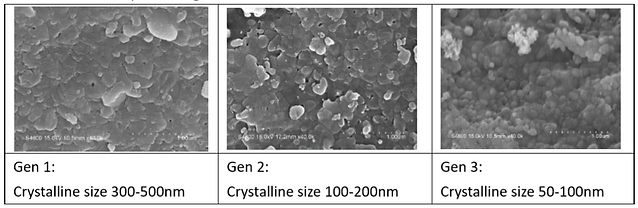

From 1980s the ceramic alumina abrasive grains was developed, there are several update of technology. At least 3 generation product was developed. The main direction is to meet the high efficiency requirement of grind tool. The roadmap is to improve sharpness and keep the toughness at certain level.

One of the direction is to make smaller crystalline size. As below pic show, the size decrease from 500nm to 50 nm. More tiny of crystalline size will improve the sharpness. And need add other additive to keep the toughness.

Below is the structure of grind tool that use precise forming grains.

-

Previous:No

Chinese

Chinese English

English