Bonded Abrasives is the grinding tool of a solid form boned into by natural or synthetic abrasive grains, usually in the shape of a wheel. The bond could be vitrified, resin, rubber etc. Vitrified and resin bond wheel are most popular.

Bonded wheel consists of grain, bond, porosity. Grain is critical for grinding and ceramic grain can significantly increase wheel life and grinding efficiency.

For vitrified bonded wheel, due to self-sharpening feature of ceramic grain, wheel grade and structure could be adjusted accordingly to fit to application demand. Decrease wheel dressing frequency, hence in increasing wheel life, and increase wheel infeed, hence give higher grinding efficiency.

Case Study A:

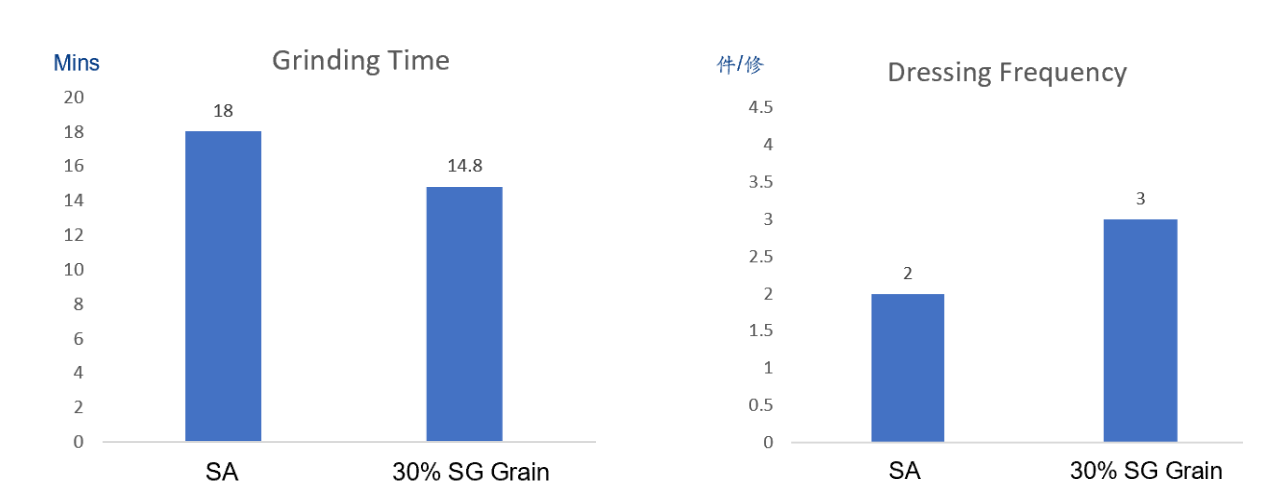

Bonded ceramic grain wheel. (Internal grinding) – by Roy SGS (ceramic grain with particle-shape)

The grinding theory is different between conventional grain and ceramic grain. For conventional grain, the grain is broken at micro-meter size to have the edges for grinding. But for ceramic grain, it’s broken at nano-meter size. The edges are much more for grinding.

Roy SGS grain crystalline is even smaller than 1st generation ceramic grain, which is well applied for grinding alloy, hard Cr-steel used in aerospace, auto etc. Wheel manufacture usually have this grain blended with conventional grain to low down the wheel cost.

Case Study B:

Bonded ceramic grain wheel. (Linear motion guide rail) – by Roy TGA (ceramic grain with rod-shape)

Roy TGA grain is a long rod-shape grain, is applied for high efficiency grinding.

Roy TGA grain length / dia ration could be: 4:1 to 8:1. the longer the grain, the more open of the structure, more benefit for coolant working. Especially the length/dia = 8:1 grain, is the first shaped abrasive that holds an open structure without pore inducer. The wheel homogeneity, open, self-sharpening are all at the perfect situation.

The typical applications are: large bearing race grinding, aerospace, linear motion guide grinding, gear grinding including form gear, bevel gear and large modules worm gear grinding.

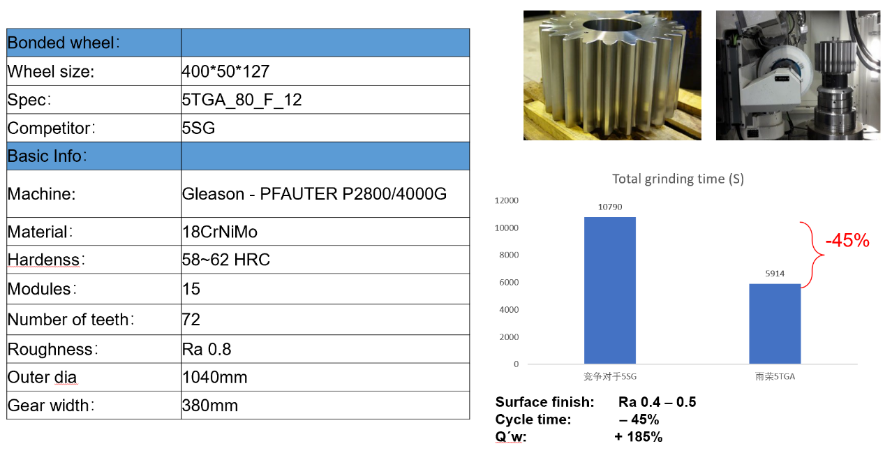

Case Study C:

Bonded ceramic grain wheel. (Form Gear Grinding) – by Roy TGA (ceramic grain with rod-shape)

Roy TGA grain is a long rod-shape grain, is applied for high efficiency grinding.

Roy TGA grain length / dia ration could be: 4:1 to 8:1. the longer the grain, the more open of the structure, more benefit for coolant working. Especially the length/dia = 8:1 grain, is the first shaped abrasive that holds an open structure without pore inducer. The wheel homogeneity, open, self-sharpening are all at the perfect situation.

The particular applications are: large bearing race grinding, aerospace, linear motion guide grinding, gear grinding including form gear, bevel gear and large modules worm gear grinding.

Download:

-

Previous:Roy Product Case Study Fo…

Chinese

Chinese English

English